Fast & accurate way of Digitalising

About Sccan Elite

We have established ourselves as industry leaders in cutting-edge technologies, including 3D Scanning, Reverse Engineering, Quality Inspection, Analysis, and 3D printing. With a wide array of services, we cater not only to the engineering and non-engineering sector but also extend our expertise to various other industries. Our unwavering commitment is to deliver unparalleled customer satisfaction by harnessing the knowledge and skills of our dedicated team of experienced engineers. We prioritize delivering projects that adhere to international standards, while continually embracing the latest technological advancements to exceed customer expectations and help them achieve their desired goals.

Vision

- At our company, we strive to be at the forefront of the industry by continuously developing…

Mission

- our main goal is to make sure our customers are happy and satisfied with our work…

About SccanElite

- we have established ourselves as industry leaders in cutting-edge technologies…

Our Services

We believe in complete customer satisfaction.

Sectors we serve

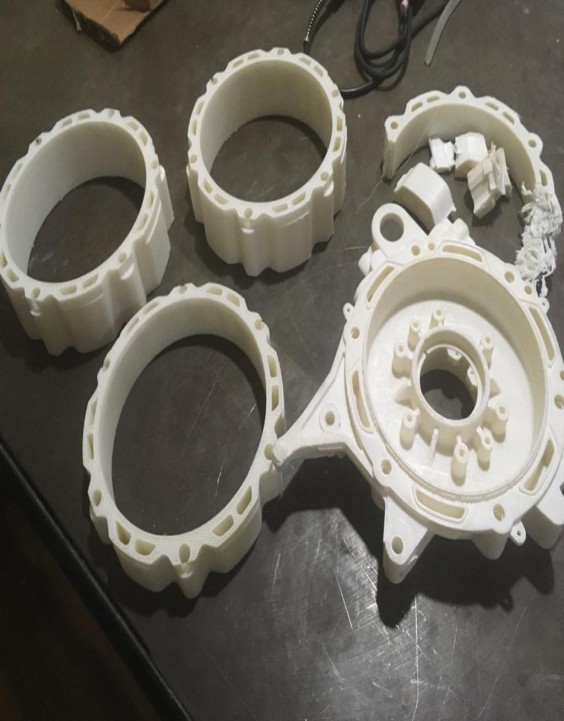

If you don’t have component’s drawings or 3d digital file then how are you going to manufacture the component?

Orginal part

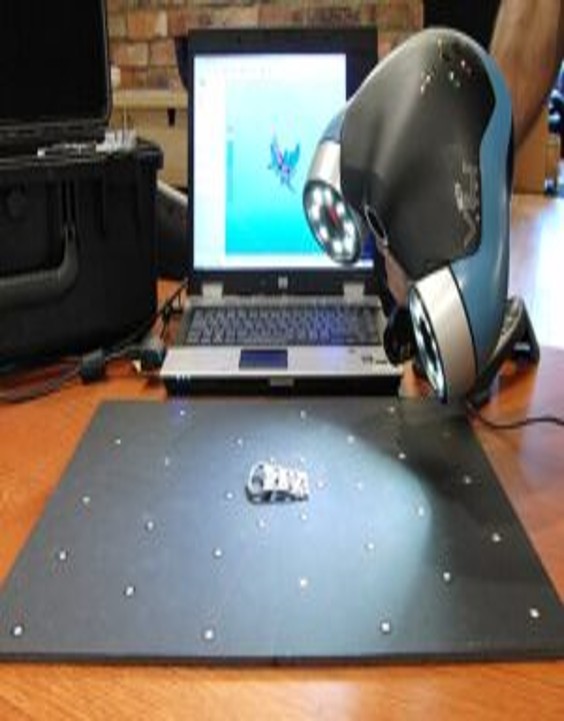

Point cloud Data

Model

Quality and Inspection

Our Inspection Services encompass a comprehensive range of capabilities

1. Verifying component measurements and tolerances: We meticulously inspect and validate component measurements and tolerances to ensure they meet the required standards.

2. Convert 3D scanned data into 3D design file format (Scan to CAD): Our expertise allows us to accurately convert 3D scanned data into the desired 3D design file format, facilitating seamless integration into the CAD workflow.

3. 3D model verification for additive manufacturing: We conduct thorough inspections of 3D models to verify their suitability for additive manufacturing processes, ensuring optimal quality and functionality.

4. Tolerances & Complex Geometry checks: Our inspection services include rigorous checks on tolerances and complex geometries, ensuring that components adhere to specified design requirements.

5. Reports and analysis: We provide detailed reports and comprehensive analysis, offering valuable insights into the inspection results, deviations, and any necessary corrective actions.